The MASTER cut 1000 is a safe and precise sawing and milling table, or can be used as a sturdy workbench or joiner's bench well-appointed and with excellent functionality.

Sawing and milling table

- For all jigsaws and circular saws with a cutting depth of up to 66 mm

- complete kit includes split insert, push stick, switch clamp and safety switch

- for all routers in combination with parallel stop and curve guide

solid, impact resistant MDF work surface, 455 x 540 mm

http://www.wolfcraft.de/workarea/supplier/sWolfcraft/documents/BAL/6165_ab_04_2006.pdf

http://www.wolfcraft.de/workarea/supplier/sWolfcraft/documents/Leaflets/evp_mastercut1000_en.pdf

=================

A Dedicated Dado Sled for the Table Saw

AppJourneyman

The Apprentice and The Journeyman provides a woodworking video tutorial on how to make a Dedicated Dado Sled for the table saw. The Dado Sled gives the woodworker control and accuracy as well as a measure of safety. This sled is great when used for woodworking joinery. (Tenons, half laps, rabbets, dadoes, and dentil mouldings to name a few.

Visit...TheApprenticeandThe Journeyman.com

===================

Make a table saw sled

===================

http://www.youtube.com/user/EagleLakeWoodworking

===================

How to build a table saw sled

===================

Table saw mobile base

===================

Table saw extension for router

===================

Table Saw LS Super System

The Incra TS-LS offers the one thing that every table saw fence should have, but none of them do: Automatic Positioning Control. All other table saws depend on a tape measure and your eyesight to position your work. That's why all table saw users are resigned to the fact that a good cut requires long set-up times and endless trial and error.

The Incra TS-LS completely eliminates the need for these tedious processes by using Incra's patented lead screw technology to position your work instantly and automatically to within 0.002". Even better, if you want to repeat a cut, you can return to any former position in less than 5 seconds with ZERO repeatability error. This kind of accuracy and perfect repeatability are luxuries that woodworkers could only dream about before the Incra TS-LS.

And because of its structural design, centrally placed carriage, and optimized side mounted clamping system, the entire unit virtually welds itself together into one solid block of steel and aluminum when locked in place. The result is exceptional strength, rigidity and stability.

With the included Wonder Fence Heavy Duty Split Fence and a full complement of Incra's routing accessories including the Master Reference Guide and Template Library with 51 Joinery Templates, the LS Instructional DVD, the Right Angle Fixture, and the Shop Stop Positioner, you'll turn any table saw into a powerhouse work station for all your ripping, cross cutting and routing requirements. (Router table extension wing sold separately.)

The Incra TS-LS offers the one thing that every table saw fence should have, but none of them do: Automatic Positioning Control. All other table saws depend on a tape measure and your eyesight to position your work. That's why all table saw users are resigned to the fact that a good cut requires long set-up times and endless trial and error.

The Incra TS-LS completely eliminates the need for these tedious processes by using Incra's patented lead screw technology to position your work instantly and automatically to within 0.002". Even better, if you want to repeat a cut, you can return to any former position in less than 5 seconds with ZERO repeatability error. This kind of accuracy and perfect repeatability are luxuries that woodworkers could only dream about before the Incra TS-LS.

And because of its structural design, centrally placed carriage, and optimized side mounted clamping system, the entire unit virtually welds itself together into one solid block of steel and aluminum when locked in place. The result is exceptional strength, rigidity and stability.

With the included Wonder Fence Heavy Duty Split Fence and a full complement of Incra's routing accessories including the Master Reference Guide and Template Library with 51 Joinery Templates, the LS Instructional DVD, the Right Angle Fixture, and the Shop Stop Positioner, you'll turn any table saw into a powerhouse work station for all your ripping, cross cutting and routing requirements. (Router table extension wing sold separately.)

=================

=================

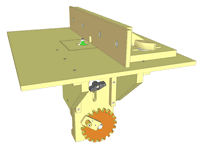

Router table for the table saw

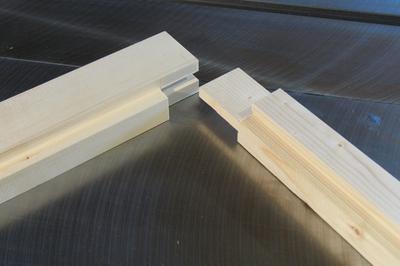

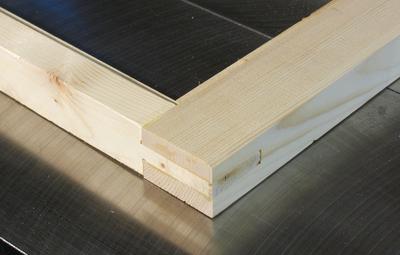

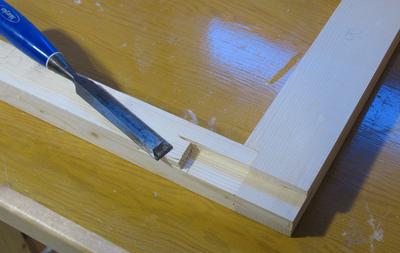

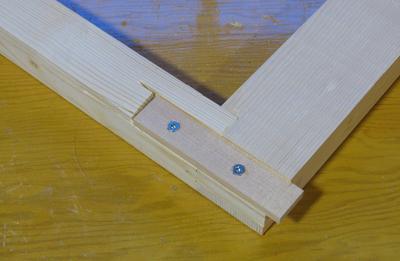

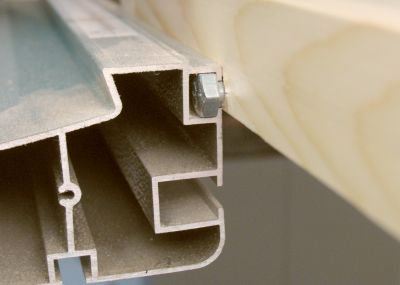

So the logical thing to do is to build some sort of frame to go on the right side of the table to extend the table. And the logical thing to do for this is to make it so that a router can be mounted under it. This has the advantage that both the table saw fence, and potentially the T-slot can be used with the router.  I built the frame out of spruce from 2x4's. The corners are joined with a simple double lap joint. The picture at left shows the joint before gluing. I built the frame out of spruce from 2x4's. The corners are joined with a simple double lap joint. The picture at left shows the joint before gluing.Note the rabbet on the inside edges. This is to support the plywood panel under which the router is mounted. Also note how the left part of the lap joint is stepped to be narrower where the joint is. If the lap joint were to go across the full width of the piece, then my rabbet would cause a gap in the frame at the corner, which would look sily.  The lap joint assembled, and trimmed to size. I made the pieces so the frame would be slightly larger than needed, so I could cut the frame precisely to size and the joints flush. The lap joint assembled, and trimmed to size. I made the pieces so the frame would be slightly larger than needed, so I could cut the frame precisely to size and the joints flush. To support the frame vertically in the fence rails, I cut away part of each corner on the bottom side of the frame, so I could screw small pieces of maple in to have them extend into the slot on the fence rails. I guess I could have made this an integral part of the frame, but by making it a separately screwed in part, I could still shim it up to bring it exactly level with the table. To support the frame vertically in the fence rails, I cut away part of each corner on the bottom side of the frame, so I could screw small pieces of maple in to have them extend into the slot on the fence rails. I guess I could have made this an integral part of the frame, but by making it a separately screwed in part, I could still shim it up to bring it exactly level with the table. And with he piece of maple screwed in. The piece of maple extends only a little past the frame, as the slot in the aluminium rail is not that deep. And with he piece of maple screwed in. The piece of maple extends only a little past the frame, as the slot in the aluminium rail is not that deep. I also added a bolt to lock the frame against the fence rails. The bolt head on the nearer side slides into the fence rail. The gap in the aluminum rail is just narrow enough to keep the bolt head from turning. I also added a bolt to lock the frame against the fence rails. The bolt head on the nearer side slides into the fence rail. The gap in the aluminum rail is just narrow enough to keep the bolt head from turning. Shown at left is how the bolt head fits snugly into the aluminium rail. Shown at left is how the bolt head fits snugly into the aluminium rail. And here the frame is mounted on the saw. I also added a leg to the frame to support the extended table. And here the frame is mounted on the saw. I also added a leg to the frame to support the extended table.Also note the piece of aluminium on the far side of the frame. This part came with the saw, and I guess the idea was that if one didn't build a table extension, one could always move that between the rails where the fence was to be clamped, to give the rails a little bit of bracing against the fence clamp. Kind of a feeble approach, but I figured I might as well use that piece of extension to extend the table a little bit more.  And with the router mounted. I still need to build a fence to attach to the saw's fence. That way, I get the adjustment feature for free. And with the router mounted. I still need to build a fence to attach to the saw's fence. That way, I get the adjustment feature for free.

See also:

More on my Table saw |

No comments:

Post a Comment