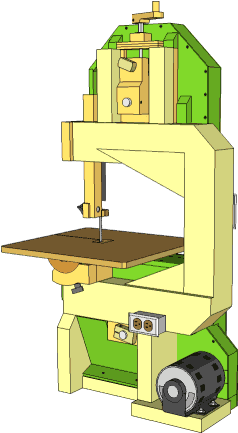

Band saw stand plans

printer friendly version

Sketchup model

-------------------

woodgears.ca/bandsaw/stand.html

woodgears.ca/bandsaw/homemade.html

(look for video at link) This project started when people started asking me about plans for my original homemade bandsaw. I didn't want to give people plans for that one, because I already had ideas for how to build an even better one.

This second bandsaw is a 16" bandsaw. I chose that size because that's the largest I could

go while still using a 105" blade. 105" blades are used by 14" bandsaws with riser blocks, so

that length is very commonly available and in stock at most woodworking stores.

This second bandsaw is a 16" bandsaw. I chose that size because that's the largest I could

go while still using a 105" blade. 105" blades are used by 14" bandsaws with riser blocks, so

that length is very commonly available and in stock at most woodworking stores.

I had been thinking about making a C-shaped wooden beam for the frame of my second bandsaw. My first thought was to join some pieces of beam together with my screw advance box joint jig, but that would make it necessary for people to build that jig before building the bandsaw. My next idea was to form the beam by laminating individual boards together. That way, I could overlap them at the corners and joints, making for a very rigid frame.

You can click on this image, or any other image in this article to get a larger view.

I glued the frame up one layer at a time, letting the glue dry before adding

the next one. That way, I only had to worry about lining up one layer at a time.

I ended up using all of my small clamps every time I glued up a layer. Building up

the frame extended over the course of a day and a half, as I'd always go and do something

else between layers.

I glued the frame up one layer at a time, letting the glue dry before adding

the next one. That way, I only had to worry about lining up one layer at a time.

I ended up using all of my small clamps every time I glued up a layer. Building up

the frame extended over the course of a day and a half, as I'd always go and do something

else between layers.

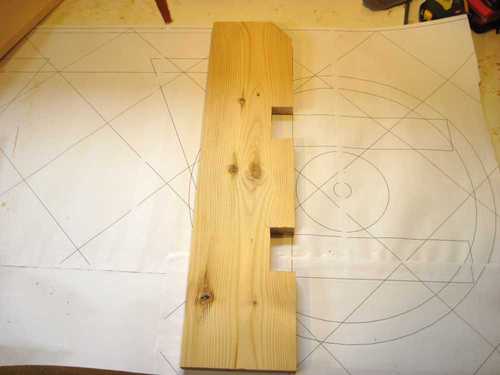

I made a 1:1 scale printout of the frame from my plan by printing it as multiple sheets

of paper and then gluing them together. I added a diagonal grid to help line up my sheets of paper.

I discovered that the diagonal grid really helped line up multiple sheets with my

gear template generator. I segmented this drawing into sheets manually, but later wrote

a program, BigPrint to make it easier to make large printouts like that.

The 1:1 printout came in very handy for checking the dimensions of the pieces I cut - it was just

a matter of laying them on the sheet.

I made a 1:1 scale printout of the frame from my plan by printing it as multiple sheets

of paper and then gluing them together. I added a diagonal grid to help line up my sheets of paper.

I discovered that the diagonal grid really helped line up multiple sheets with my

gear template generator. I segmented this drawing into sheets manually, but later wrote

a program, BigPrint to make it easier to make large printouts like that.

The 1:1 printout came in very handy for checking the dimensions of the pieces I cut - it was just

a matter of laying them on the sheet.

The completed frame is quite light, under 30 pounds (15 kg) in weight, which makes the

bandsaw easy to move.

When I measured how much the fame flexed from tensioning the blade, I found that it was stiffer

than the frame on my cast iron bandsaw.

This may seem a little surprising, but consider the following figures I gathered from the internet:

The completed frame is quite light, under 30 pounds (15 kg) in weight, which makes the

bandsaw easy to move.

When I measured how much the fame flexed from tensioning the blade, I found that it was stiffer

than the frame on my cast iron bandsaw.

This may seem a little surprising, but consider the following figures I gathered from the internet:

| Material | Young's modulus |

|---|---|

| Steel | 200 GPa |

| Cast iron | 80 GPa |

| Pine | 9 GPa in the grain direction |

Wheel and wheel mounts

I was pretty sure the nice birch plywood would do for wheels, but I wanted to see how cheaply

it was possible to build a bandsaw. I had some scavenged plywood that was 12 mm thick. I used

two layers of 12 mm, and another layer of 5 mm in between.

This plywood was ordinary plywood, although a slightly better grade

than the packing crate plywood I tried for my initial bandsaw wheel

experiments on my first bandsaw.

I used lots of clamps to glue it up. I wanted to be sure I had a good solid

glue joint, especially around the edges of the wheels.

I was pretty sure the nice birch plywood would do for wheels, but I wanted to see how cheaply

it was possible to build a bandsaw. I had some scavenged plywood that was 12 mm thick. I used

two layers of 12 mm, and another layer of 5 mm in between.

This plywood was ordinary plywood, although a slightly better grade

than the packing crate plywood I tried for my initial bandsaw wheel

experiments on my first bandsaw.

I used lots of clamps to glue it up. I wanted to be sure I had a good solid

glue joint, especially around the edges of the wheels.

I shaped the rims of the wheels by using the wheels like a lathe.

With the wheel turning on its own bearings, any eccentricity I had with how

I mounted them got cut away as I turned the wheel down to it's final size.

I shaped the rims of the wheels by using the wheels like a lathe.

With the wheel turning on its own bearings, any eccentricity I had with how

I mounted them got cut away as I turned the wheel down to it's final size.

I did encounter a few voids in the plywood that I had to fill, but I didn't bother filling small voids near the edges. But the middle of the wheel, where the blade normally runs, has to be solid.

I spun up the wheels using a temporary pulley that I screwed to the side of the wheels. This allowed me to turn both the top and bottom wheels, as well as the main drive pulley for the bottom wheel. I made the temporary pulley on the table saw, similar to how I made the one for my other bandsaw

It was at about this stage of progress that I shot my messy workshop video, so you can see pieces of the bandsaw around my shop in the video.

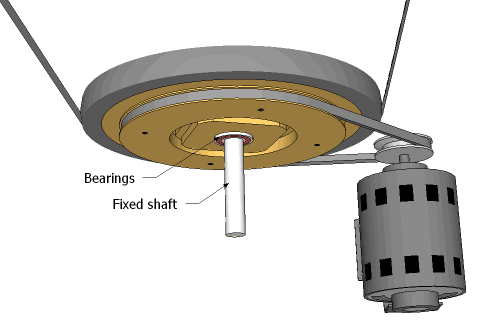

The bottom wheel in my new design spins on a fixed shaft, much like the top wheel does.

A drive pulley is screwed directly to the back of the bottom wheel.

The advantage to this approach is that there is no need to couple wheels and pulleys to the shaft.

The other advantage is that the force from the blade tension is divided between two bearings.

The bottom wheel in my new design spins on a fixed shaft, much like the top wheel does.

A drive pulley is screwed directly to the back of the bottom wheel.

The advantage to this approach is that there is no need to couple wheels and pulleys to the shaft.

The other advantage is that the force from the blade tension is divided between two bearings.

This is the top wheel mount, as seen from the front.

The "tension spring" consists of three thin strips of wood across the top of the frame.

These are meant to bend and act as a spring as tension is increased.

I opted for a simple crank for the tensioning mechanism on this saw. The shape of the frame

would have made the lever and ratcheting mechanism that I used on my other bandsaw awkward.

I also wanted to keep this bandsaw simple and easy to build. The crank makes it really

easy to tension up the bandsaw - I can turn it from no tension to full tension in about three

seconds.

This is the top wheel mount, as seen from the front.

The "tension spring" consists of three thin strips of wood across the top of the frame.

These are meant to bend and act as a spring as tension is increased.

I opted for a simple crank for the tensioning mechanism on this saw. The shape of the frame

would have made the lever and ratcheting mechanism that I used on my other bandsaw awkward.

I also wanted to keep this bandsaw simple and easy to build. The crank makes it really

easy to tension up the bandsaw - I can turn it from no tension to full tension in about three

seconds.

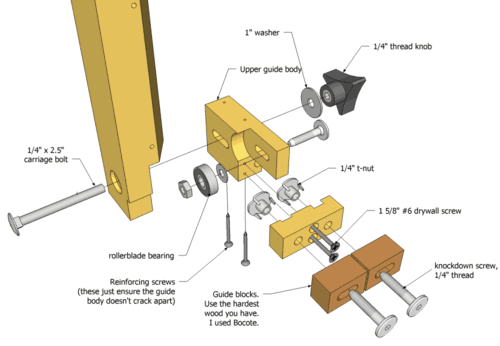

Blade guides

I was originally going to use Lignum Vitae, the hardest of the hardwoods, for the guide blocks.

But then I went through my box of exotic off cuts that I bought for

this article and tried rubbing each one on my cast iron table saw table

to see how slippery they were. The bocote slid the easiest, so I used that.

I was originally going to use Lignum Vitae, the hardest of the hardwoods, for the guide blocks.

But then I went through my box of exotic off cuts that I bought for

this article and tried rubbing each one on my cast iron table saw table

to see how slippery they were. The bocote slid the easiest, so I used that.

But you don't need to get bocote. Any hardwood will do, the heavier the better. I'm still using the original oil soaked maple guide blocks on my other bandsaw.

This drawing shows how the blade guides go together. The top and bottom blade guides

are nearly identical in design.

You can click on this drawing, or any of the other pictures in this article for a larger view.

This drawing shows how the blade guides go together. The top and bottom blade guides

are nearly identical in design.

You can click on this drawing, or any of the other pictures in this article for a larger view.

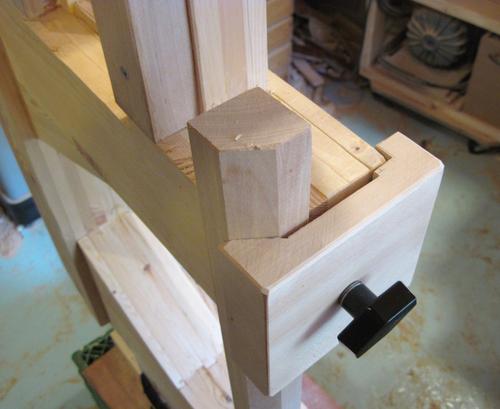

The guide bar is pressed against a notch in the frame. I put a bevel on it where it clamps

on so that it gets pressed into the corner, which rigidly holds it in place.

The guide bar is pressed against a notch in the frame. I put a bevel on it where it clamps

on so that it gets pressed into the corner, which rigidly holds it in place.

Because of space constraints, the blade guard above the top blade guide is made out of sheet metal.

The guard needs to be able to fit around the top wheel, yet also slide into the top wheel enclosure.

Because of space constraints, the blade guard above the top blade guide is made out of sheet metal.

The guard needs to be able to fit around the top wheel, yet also slide into the top wheel enclosure.

The best source of sheet metal I could think of was to cut it out of an old PC case with an angle

grinder. I cut the piece off the corner, so I already had one bend in the piece. I then used my vise

as a sort of "metal brake" to make the second right angle bend.

The best source of sheet metal I could think of was to cut it out of an old PC case with an angle

grinder. I cut the piece off the corner, so I already had one bend in the piece. I then used my vise

as a sort of "metal brake" to make the second right angle bend.

No comments:

Post a Comment